The Design and Implementation of a Robotic Arm Digital Twin System Based on ESP32

Keywords:

Digital Twin Technology, Robotic Arm Control System, ESP32, 3D Visualization, Voice ControlAbstract

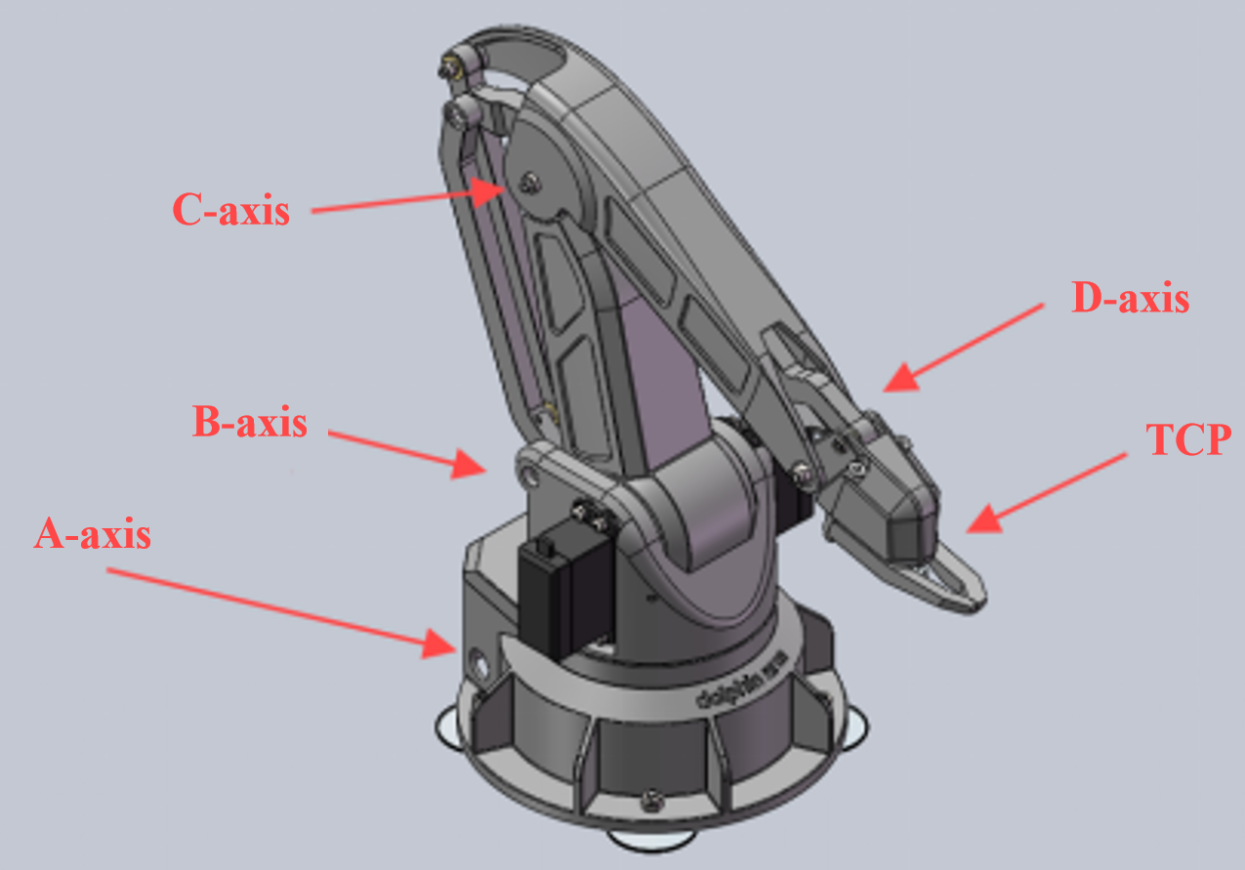

This paper designs and implements an ESP32-based digital twin system for a robotic arm. The system innovatively utilizes digital twin technology to achieve real-time monitoring, remote control, and virtual-real synchronization of the robotic arm through bidirectional mapping and real-time interaction between the virtual and real worlds. It aims to address the issues of complex operation, high safety risks, and expensive costs associated with traditional industrial robot teaching. The hardware component of the system is designed based on a 1:7 scaled-down version of the ABB IRB-460 robotic arm, with non-standard parts manufactured using 3D printing technology. ESP32 is employed as the control core, replacing the traditional high-cost industrial robot system control cabinet. In the software component, this paper not only constructs a virtual robotic arm model and realizes three-dimensional visualization through Unity3D but also specifically develops an APP-end teaching pendant. This teaching pendant not only supports users in controlling the robotic arm through a UI control panel but also introduces ChatGPT technology to enable remote control of the robotic arm via voice commands. Experimental results demonstrate that the system possesses high virtual-real consistency and operational stability, effectively lowering the learning threshold and significantly enhancing students' understanding and practical abilities in industrial robot operations. It provides an efficient and innovative solution for industrial robot teaching.

References

Li, Bh., Hou, Bc., Yu, Wt. et al. (2017). Applications of artificial intelligence in intelligent manufacturing: a review. Frontiers Inf Technol Electronic Eng 18, 86–96. https://doi.org/10.1631/FITEE.1601885

Ritchie, E. ., & Landis, E. A. (2021). Industrial Robotics in Manufacturing . Journal of Leadership, Accountability and Ethics, 18(2). https://doi.org/ 10.33423/jlae.v18i2.4258

Zhao, Yantong, Said, Rusmawati, Ismail, Normaz Wana, Hamzah, Hanny Zurina. (2022). Effect of Industrial Robots on Employment in China: An Industry Level Analysis, Computational Intelligence and Neuroscience, 13. https://doi.org/10. 1155/2022/2267237

Valeria Villani, Fabio Pini, Francesco Leali, Cristian Secchi. (2018).Survey on human–robot collaboration in industrial settings: Safety, intuitive interfaces and applications, Mechatronics, 55, 248-266, https://doi.org/10.1016/j.mechatronics. 2018.02.009.

Kaczmarek, W., Lotys, B., Borys, S., Laskowski, D., & Lubkowski, P. (2021). Controlling an Industrial Robot Using a Graphic Tablet in Offline and Online Mode. Sensors, 21(7), 2439. https://doi.org/10.3390/s21072439

Liu, Y., Kukkar, A. & Shah, M. (2022). Study of industrial interactive design system based on virtual reality teaching technology in industrial robot. Paladyn, Journal of Behavioral Robotics, 13(1), 45-55. https://doi.org/10.1515/pjbr-2022 -0004

Chen, X. (2023). Bilingual course of industry robot basing digital twin technology. Journal of Education and Educational Research, 3(1), 29-31. https://doi.org/10.54097/jeer.v3i1.8059

Huang, Y., Wu, X., Yang, B., Li, Z. (2020). The Application of Industrial Robot Technology in the Teaching of Applied Undergraduate Colleges and Universities. In: Abawajy, J., Choo, KK., Islam, R., Xu, Z., Atiquzzaman, M. (eds) International Conference on Applications and Techniques in Cyber Intelligence ATCI 2019. ATCI 2019. Advances in Intelligent Systems and Computing, vol 1017. Springer, Cham. https://doi.org/10.1007/978-3-030- 25128-4_3

Garg, G., Kuts, V., & Anbarjafari, G. (2021). Digital Twin for FANUC Robots: Industrial Robot Programming and Simulation Using Virtual Reality. Sustainability, 13(18), 10336. https://doi.org/10.3390/su131810336

Zhang, Y., & Zhang, L. (2024). Research on Education Robot Control System Based on ESP32. Journal of Education and Educational Research, 7(2), 299-302. https://doi.org/10.54097/3x86qp78

Domènech, G.F. (2016). Construcció d'un micro braç articulat: Part mecànica.

Lundqvist, R., & Söreling, T. (2005). New Interface for Rapid Feedback Control on ABB-Robots.

Khadiri, H., Sekkat, S., & Herrou, B. (2023). Digital Twin Based SUDIHA Architecture to Smart Shopfloor Scheduling. Journal of Manufacturing and Materials Processing, 7(3), 84. https://doi.org/10.3390/jmmp7030084

Hindroyuwono, R., Marvianto, R. A., Almaida, E. F., & Arafat, Y. . B. (2024). Static Loading Simulation on Temporary Platform and Ladder Absorbent Chamber Design. International Journal of Engineering Continuity, 3(1), 118–125. https://doi.org/10.58291/ijec.v3i1.247

Khan, A. (2021). Study of an at-home upper-extremity stroke rehabilitation system (Master's thesis, University of Calgary, Calgary, Canada). Retrieved from https://prism.ucalgary.ca.

He, B., Bai, KJ. (2021). Digital twin-based sustainable intelligent manufacturing: a review. Adv. Manuf,9, 1–21 .https://doi.org/10.1007/s40436-020-00302 -5

Sun, X., Zhang, F., Wang, J. et al.(2025). Digital twin for smart manufacturing equipment: modeling and applications. Int J Adv Manuf Technol 137, 4929–4946.https://doi.org/10.1007/s00170-025-15468-0

Wang, C., Liu, X., Feng, F. et al.(2025). A modeling method of digital twin connection model based on virtual sensor. J Intell Manuf. https://doi.org/10. 1007/s10845-025-02639-9

Craig, J.J. (1986). Introduction to Robotics Mechanics and Control.